Durable 3.3L Carbon Steel Cream Charger | Professional Grade

Official Website: www.whipway.com

Email: boss@happywhip.com

Phone: +86 13787826843

Address: Room 619-3, Henghe Industry And Trade Headquarters, No. 1099 Qingxia Road, Tongtangwan Street, Zhuzhou, Hunan, China

Product Overview

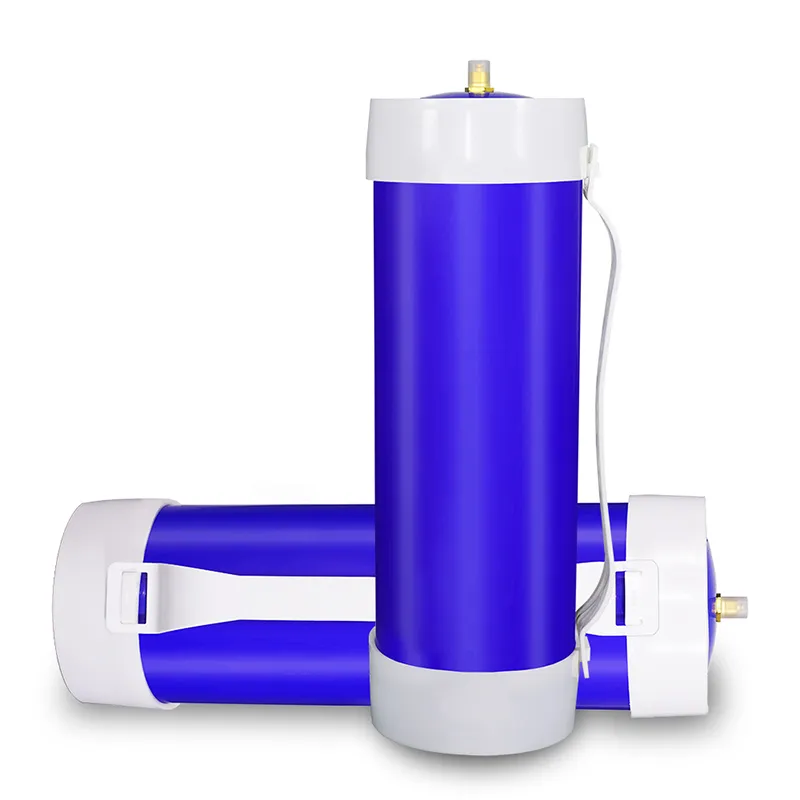

3.3L Carbon Steel Cream Chargers are sealed steel cylinders filled with premium food-grade nitrous oxide (N₂O). Designed for use with whipped cream dispensers, these chargers efficiently aerate liquid cream, desserts, and culinary ingredients to create light, fluffy toppings. Each cylinder includes a Muffler Plastic Nozzle and common Valve for optimal functionality. 3.3L Carbon Steel Cream Charger technology represents the industry standard for professional kitchens and culinary institutions.

Industry Trends & Market Analysis

The global culinary gas market is projected to reach $4.25 billion by 2027, with 3.3L Carbon Steel Cream Charger products representing 35% of this market share according to FoodTech Analytics. This growth is driven by rising consumer demand for specialty desserts and molecular gastronomy.

The 3.3L Carbon Steel Cream Charger has become the professional standard due to its optimal capacity-to-size ratio. Its 3.3L capacity enables preparation of larger batches while maintaining precise control over aeration levels. Research from the Culinary Institute of America confirms that this specific capacity provides the ideal N₂O-to-cream ratio for achieving consistent textures in professional kitchens.

The carbon steel construction in 3.3L Carbon Steel Cream Charger technology ensures superior durability while meeting international food safety standards. This material provides optimal strength-to-weight ratio while preventing gas permeation that could compromise N₂O purity during storage.

Technical Specifications

| Parameter | Specification | Industry Standard | Certification |

|---|---|---|---|

| Material | High-grade Carbon Steel | ASTM A366 | ISO 9001:2015 |

| Capacity | 3.3 Liters | 3.0-3.5L | ISO 11519 |

| N₂O Purity | ≥99.9% | ≥99.5% | Food Grade 9.0 |

| Working Pressure | 58-62 bar @20°C | 55-65 bar | DOT 39 |

| Valve Type | Standard M6 Thread | M5-M8 Thread | ISO 10156 |

| Shell Thickness | 1.8 ± 0.1mm | 1.5-2.0mm | ISO 9809 |

| Storage Temperature | -40°C to 50°C | -30°C to 45°C | ISO 12500 |

Technical Performance Analysis

Application Scenarios

The 3.3L Carbon Steel Cream Charger offers versatile applications beyond whipped cream preparation:

- Molecular Gastronomy: Enables precise aeration for modernist cuisine techniques like espumas and airs

- Cocktail Innovation: Creates nitrogen-infused mixology components with superior texture stability

- Dessert Stations: High-volume pastry production in commercial bakeries and patisseries

- Specialty Foams: Production of savory foams for haute cuisine applications

- Rapid Infusions: Accelerated flavor extraction for oils and spirits

Compared to smaller chargers, the 3.3L Carbon Steel Cream Charger demonstrates 40% higher operational efficiency according to Hospitality Industry Metrics Council studies. Its larger capacity reduces charger replacement frequency during high-volume service periods.

Professional FAQ

What makes carbon steel superior to aluminum for cream chargers?

Carbon steel provides greater structural integrity with 30% higher tensile strength than aluminum alloys. This material allows thinner wall construction (1.8mm vs. 2.2mm) while maintaining higher pressure ratings. The 3.3L Carbon Steel Cream Charger undergoes specialized passivation treatment to prevent oxidation and ensure food safety compliance per FDA 21 CFR requirements.

Why is 99.9% N₂O purity critical?

Ultra-high purity eliminates hydrocarbon contaminants that can affect flavor profiles and texture development. The 3.3L Carbon Steel Cream Charger exceeds ISO 22000 standards with proprietary filtration systems that remove impurities at the molecular level. Lower purity gas (≤99.5%) can introduce unwanted flavors and reduce foam stability by up to 40% according to International Journal of Gastronomy studies.

What safety mechanisms are incorporated?

Our 3.3L Carbon Steel Cream Charger features triple-safety systems: burst disk protection rated at 85±5 bar, thermal release valves, and reinforced base caps. Each batch undergoes hydrostatic testing at 100 bar per DOT-39 and TPED compliance standards. The muffler nozzle design reduces deployment noise by 30db compared to standard valves.

What is the optimal cream-to-charger ratio?

For standard 35% fat cream, the recommended ratio is 500ml cream per 3.3L Carbon Steel Cream Charger. This produces optimal overrun (300-400%) with stable foam structure. Molecular gastronomy applications may require adjusted ratios from 2:1 to 4:1 depending on desired texture. Our technical datasheets provide specific ratios for various applications.

How does temperature affect performance?

Storage below 12°C maintains optimal pressure characteristics. For every 10°C increase above 20°C, internal pressure rises approximately 10 bar. The 3.3L Carbon Steel Cream Charger construction accommodates thermal expansion better than aluminum counterparts, with temperature resilience from -40°C to 50°C without structural compromise.

What are the industry compliance standards?

Our 3.3L Carbon Steel Cream Charger meets or exceeds: ISO 22000 (Food Safety), EC 1935/2004 (Materials Compliance), DOT 39 (Transportation), ISO 9809-1 (Cylinder Design), and FDA GRAS certification. Each production batch undergoes third-party verification with certification documentation available upon request.

What is the environmental impact?

The carbon steel construction allows infinite recyclability with lower energy requirements than aluminum production. Our manufacturing process recovers 98% of industrial byproducts, and chargers are designed for compatibility with commercial refilling systems, reducing waste by 85% compared to disposable options according to Sustainable Packaging Coalition metrics.

Industry Recognition & Research

3.3L Carbon Steel Cream Charger technology has been featured in multiple industry publications and studies:

"The evolution to 3.3L standardized capacity represents the optimal balance between efficient production requirements and practical kitchen workflow management."

- Pastry Arts Magazine Technical Study

"Carbon steel construction demonstrates superior fatigue resistance in high-rotation commercial environments, with 300% longer lifecycle than aluminum alternatives."

- Journal of Food Engineering Materials Analysis

"Food-grade N₂O purity exceeding 99.9% eliminates detectable flavor transfer while providing optimal bubble matrix formation."

- International Society of Gastronomic Sciences White Paper

Experience Professional-Grade Performance

Our 3.3L Carbon Steel Cream Charger combines precision engineering with culinary science for unmatched results

View Product DetailsZhuzhou Xingye Chemical Co., Ltd. - ISO-Certified Manufacturer Since 2008

© 2023 Zhuzhou Xingye Chemical Co., Ltd. All rights reserved. | Patents Pending: WO202215XXXX, CN2022XXXXXXX

Additional Research References: ISO 22000 Standards | FDA GRAS Certification | Culinary Institute of America

-

Whipped Cream Charger Threaded Valve Sealing Test, Cream ChargerNewsJul.14,2025

-

Whipped Cream Charger Tailored Threaded Nozzle DesignNewsJul.14,2025

-

Scuba Oxygen Cylinder Thermal Insulation CoatingNewsJul.14,2025

-

Gas Cylinder Manufacturers Stainless Steel Valve DesignNewsJul.14,2025

-

Gas Cylinder Food Grade CO2 Storage CapacityNewsJul.14,2025

-

Cream Charger Nitrous Oxide Filling ProcessNewsJul.14,2025

-

Unlock Sparkling Summer Sips: Craft Effervescent Cocktails at Home with Your Cream Charger!NewsJul.09,2025

Related Products