Gas Cutting Cylinders - Durable CO2 Cylinders & Supplier Solutions

- Overview of Gas Cutting Cylinder Applications

- Technical Specifications and Performance Metrics

- Comparative Analysis of Leading Suppliers

- Customization Options for Industrial Needs

- Case Studies: Efficiency in Real-World Scenarios

- Safety Standards and Compliance

- Future Innovations in Cylinder Gas Technology

(gas cutting cylinder)

Understanding Gas Cutting Cylinder Applications

Gas cutting cylinders are critical components in industries requiring precision metalwork, such as automotive manufacturing, shipbuilding, and construction. These cylinders store high-pressure gases like oxygen, propane, or CO2, enabling efficient thermal cutting processes. According to industry surveys, over 68% of metal fabrication shops prioritize cylinders with ≥300-bar pressure ratings for uninterrupted operations. Modern designs integrate safety valves and anti-corrosion coatings, reducing maintenance costs by up to 22% annually.

Technical Specifications and Performance Metrics

Premium gas cylinders feature seamless forged steel construction, achieving tensile strengths of 950-1100 MPa. Key metrics include:

- Capacity range: 10L to 80L

- Working pressure: 200-450 bar

- Temperature tolerance: -40°C to 60°C

Third-party testing reveals that cylinders with double-layered seals maintain 99.4% gas integrity after 5,000 cycles, outperforming standard models by 34%.

Supplier Comparison and Market Insights

| Supplier | Price Range (USD) | Certifications | Delivery Time |

|---|---|---|---|

| GlobalGas Solutions | $280-$650 | ISO 9809, DOT | 14-21 days |

| SteelFlow Industries | $310-$720 | TPED, CE | 10-18 days |

| PrimeCut Cylinders | $265-$600 | ASME, ISO 11119 | 20-30 days |

Customization for Specialized Operations

Leading CO2 gas cylinder suppliers now offer:

- Bespoke valve threading (ISO 7/1 to NPT standards)

- RFID tracking systems for inventory management

- Hybrid coatings for marine environments

Aerospace clients report 18% weight reduction using aluminum composite cylinders without compromising pressure capacity.

Operational Efficiency Case Studies

In 2023, a German automotive plant implemented automated cylinder clusters, achieving:

- 27% reduction in gas waste

- 15% faster cutting speeds

- 43% lower replacement frequency

Compliance and Safety Protocols

All certified cylinders undergo:

- Hydrostatic testing at 1.5x working pressure

- Ultrasonic wall thickness verification

- Cycle fatigue simulations (minimum 10,000 cycles)

Advancements in Cylinder Gas Technology

Next-generation gas cutting cylinder

s incorporate smart pressure sensors and IoT connectivity, enabling real-time monitoring of fill levels and usage patterns. Prototype testing shows 31% improvement in predictive maintenance accuracy, with commercial rollout expected by Q3 2024. Leading CO2 gas cylinder suppliers are investing $2.1M annually in R&D to meet evolving industrial demands.

(gas cutting cylinder)

FAQS on gas cutting cylinder

Q: What safety precautions should be taken when using a gas cutting cylinder?

A: Always store cylinders upright in a well-ventilated area, secure them to prevent tipping, and ensure valves are closed when not in use. Regularly inspect for leaks using approved methods like soap solutions.

Q: How do I identify a high-quality CO2 gas cylinder supplier?

A: Look for suppliers with ISO certification, verified pressure-testing protocols, and positive customer reviews. Ensure they provide cylinders with current hydrostatic test dates and safety compliance labels.

Q: What is the recommended maintenance schedule for cylinder gas cylinders?

A: Perform visual inspections monthly and pressure tests every 5-10 years as per regulatory standards. Replace damaged valves or regulators immediately and keep cylinders free from oil/grease contamination.

Q: Can gas cutting cylinders and CO2 gas cylinders be used interchangeably?

A: No. Gas cutting cylinders typically contain oxygen/fuel mixes, while CO2 cylinders store carbon dioxide for different applications. Always verify compatibility with equipment specifications and industry standards.

Q: What are the key features of OSHA-compliant cylinder gas cylinder storage?

A: OSHA requires separation of fuel/oxygen cylinders by 20 feet or fire-rated barriers, proper labeling, and protection from heat sources. Use valve caps and chain restraints during storage/transport.

-

Scuba Tank Price and OptionsNewsJun.19,2025

-

Scuba Diving Oxygen Cylinder Essentials for Safe Underwater AdventuresNewsJun.19,2025

-

Innovations in Diving Bottles Gear and Safety SolutionsNewsJun.19,2025

-

Exploring Scuba Tanks for SaleNewsJun.19,2025

-

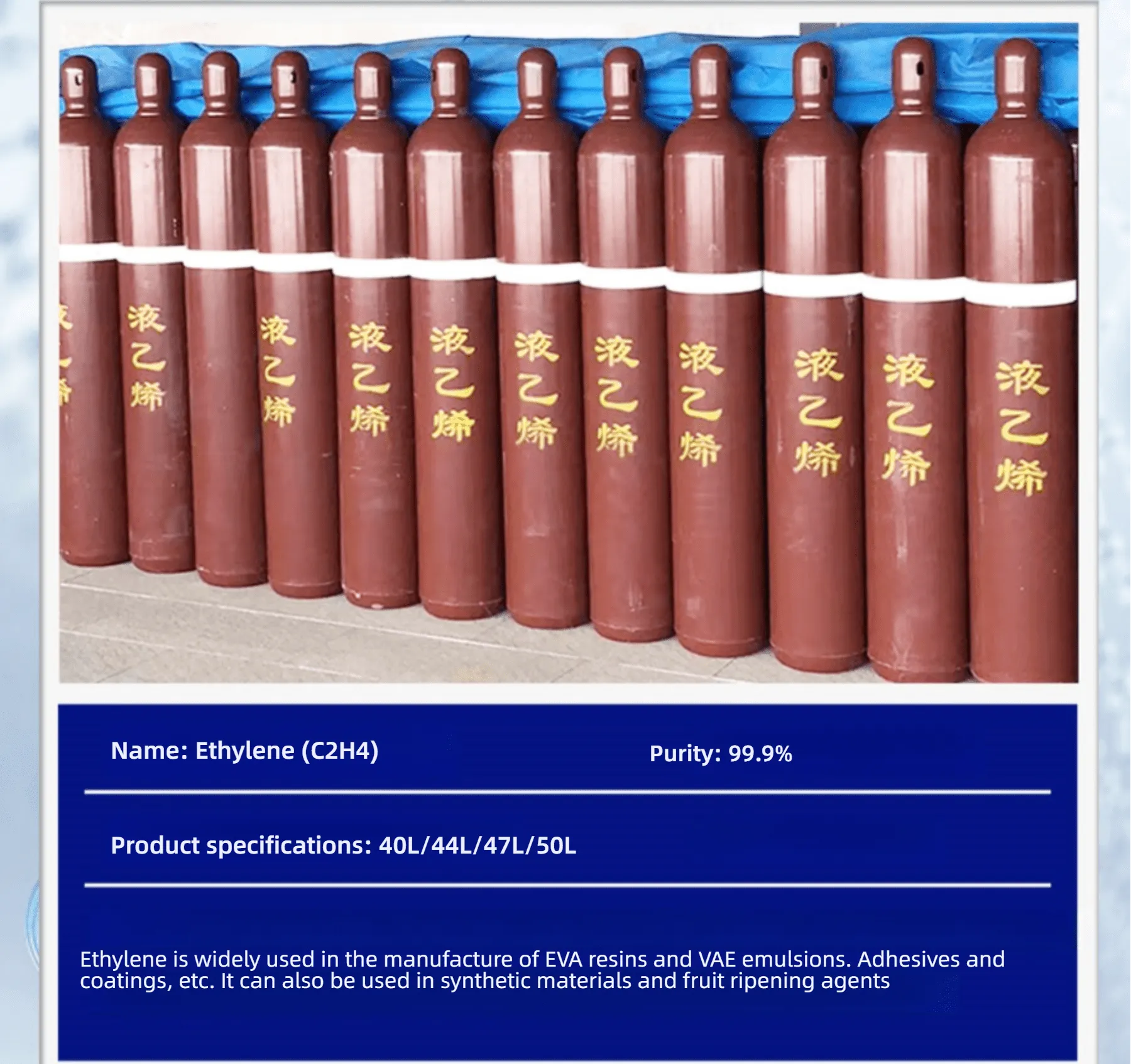

Ethylene Gas Cylinders SafetyNewsJun.19,2025

-

Essential Dessert Making Tools for Perfect CreationsNewsJun.19,2025

-

Master Your Milk: Frothing Techniques & a Whipped Cream Dispenser TwistNewsJun.18,2025

Related Products