Premium N2 & N2O Cream Chargers - Perfect Whipped Cream

The Evolving Landscape of N2O Cream Chargers: Purity, Efficiency, and Culinary Innovation

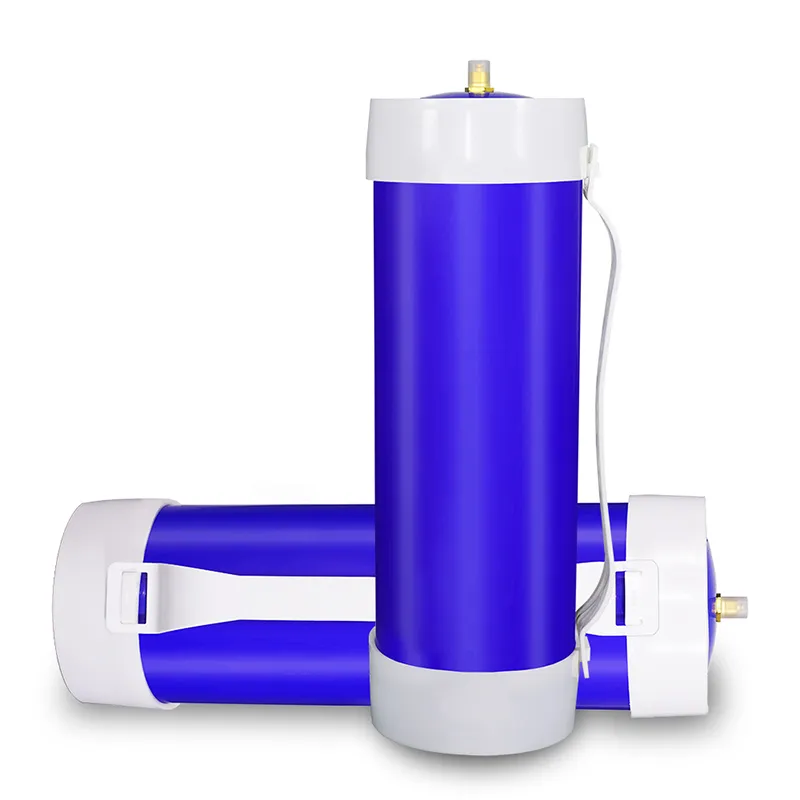

In the rapidly evolving culinary and beverage industry, the demand for high-quality, efficient tools is paramount. Among these, cream chargers stand out as essential for professionals seeking to create perfect whipped creams, delicate foams, and innovative infusions. While often searched as n2 cream chargers, the active gas is actually Nitrous Oxide (N2O), known for its stability and effectiveness in food applications. This distinction is crucial for understanding the product's true capabilities and safety profiles. Modern N2O cream chargers, especially larger capacity units like the 3.3L Carbon Steel Cream Charger, are revolutionizing efficiency and consistency in commercial kitchens and beyond.

The shift towards larger volumes and superior purity is a significant industry trend, driven by the need for reduced downtime, lower operational costs, and consistent product quality. This comprehensive overview delves into the technical aspects, manufacturing excellence, diverse applications, and market advantages of premium N2O cream chargers, ensuring B2B decision-makers have the insights needed to make informed procurement choices for their establishments.

Industry Trends and Technological Advancement in N2O Solutions

The culinary gas market is experiencing a notable pivot towards higher efficiency and larger capacity solutions. Historically dominated by 8g N2O cream chargers, the industry is now witnessing a significant uptake of larger format cylinders, such as 3.3L units, which offer substantial benefits in terms of yield and operational continuity. This trend is fueled by commercial establishments – from bustling coffee shops to high-volume catering services – that require a reliable, uninterrupted supply of N2O to maintain peak productivity. The focus is increasingly on not just the volume, but also the purity of the N2O, with 99.9% food-grade purity becoming the benchmark for safety and quality.

Technological advancements are also driving innovations in cylinder design and safety features. Manufacturers are investing in robust materials like carbon steel, combined with advanced valve systems, to ensure maximum safety and user-friendliness. The emphasis is on reducing waste, improving ergonomic handling, and providing a more sustainable option compared to numerous small cartridges. As the culinary landscape continues to innovate, so too does the technology supporting it, ensuring that professionals have access to the most advanced and reliable N2O cream chargers on the market.

Technical Specifications and Performance Parameters

Understanding the technical specifications of cream chargers N2O is crucial for evaluating performance and ensuring compatibility with various dispensing systems. Our 3.3L Carbon Steel Cream Charger, for example, is engineered to deliver superior performance. Key parameters include the gas type (Food Grade N2O), purity level (99.9%), and a substantial capacity of 2000g of N2O, equivalent to over 250 standard 8g N2O cream chargers. The cylinder material, high-grade carbon steel, ensures durability and safety under pressure, meeting stringent international standards.

The design incorporates an advanced pressure release mechanism and robust valve system, critical for consistent gas flow and user safety. Each unit undergoes rigorous testing to confirm burst pressure integrity and seal reliability, guaranteeing a dependable product. The table below provides a concise comparison of typical specifications for different types of cream chargers N20, highlighting the advantages of larger capacity units.

N2O Cream Charger Specification Comparison

| Feature | 8g N2O Cream Charger | 615g N2O Cream Charger | 3.3L (2000g) N2O Cream Charger |

|---|---|---|---|

| Gas Type | Food Grade N2O | Food Grade N2O | Food Grade N2O |

| N2O Purity | 99.5% - 99.9% | 99.9% | 99.9% |

| Capacity (N2O) | 8 grams | 615 grams | 2000 grams |

| Equivalent 8g Chargers | 1 | ~76 | ~250 |

| Cylinder Material | Recyclable Steel | Alloy/Carbon Steel | Carbon Steel |

| Typical Working Pressure | ~60 bar (870 psi) | ~60 bar (870 psi) | ~60 bar (870 psi) |

| Shelf Life (Gas) | 5+ years | 5+ years | 5+ years |

| Certifications | CE, FDA (for N2O) | CE, TUV, ISO, FDA | CE, TUV, ISO, FDA |

Precision Craftsmanship: The Manufacturing Process of N2O Cream Chargers

The production of high-purity N2O cream chargers involves a meticulous, multi-stage manufacturing process designed to ensure safety, consistency, and optimal performance. It begins with the selection of premium materials. For our 3.3L Carbon Steel Cream Charger, only food-grade carbon steel is used, chosen for its strength and resistance to corrosion, critical for containing pressurized N2O.

- Material Sourcing & Pre-treatment: High-grade carbon steel sheets are precisely cut and pre-treated to remove impurities, preparing them for deep drawing.

- Deep Drawing & Forming: Advanced hydraulic presses are employed to deep-draw the steel into seamless cylindrical forms. This process is highly controlled to ensure uniform wall thickness and structural integrity, preventing weak points.

- Precision Cleaning: Once formed, each cylinder undergoes a rigorous multi-stage cleaning process, including degreasing and rinsing with deionized water, to eliminate any manufacturing residues. This step is paramount to ensure the N2O remains untainted.

- Valve Integration & Sealing: High-precision CNC machining is used to manufacture the intricate valve components, which are then securely integrated into the cylinder. State-of-the-art sealing technology guarantees a leak-proof connection, maintaining gas integrity over extended periods.

- N2O Filling (High Purity): Cylinders are filled with 99.9% pure food-grade N2O sourced from certified suppliers. The filling process is conducted in a controlled environment to prevent contamination and ensure accurate volume.

- Multi-Stage Quality Control: Every charger undergoes comprehensive testing, including hydrostatic pressure testing to verify burst strength, leak detection using advanced spectroscopy, and final N2O purity analysis. Compliance with international standards such as ISO 9001 for quality management and CE/TUV for safety is strictly adhered to.

This meticulous production methodology ensures that each cream chargers N2O unit meets the highest benchmarks for safety, reliability, and food-grade purity, providing users with a product that consistently performs as expected.

Diverse Application Scenarios and Operational Advantages

The versatility of n20 cream chargers extends across a wide array of culinary and beverage applications, making them an indispensable tool in both professional and high-end home kitchens. Their primary function is to transform liquid ingredients into stable foams and mousses, but their utility goes far beyond simple whipped cream.

- Culinary Arts: Ideal for creating perfectly aerated whipped cream, light-as-air mousses, delicate sauces, and foams that add texture and visual appeal to dishes. The consistent pressure from high-capacity n2o cream chargers ensures uniform results every time.

- Beverage Innovation: Increasingly used for nitro cold brew coffee, infusing spirits with unique flavors, and creating foamy toppings for cocktails and specialized drinks. The inert nature of N2O also helps to preserve the freshness of infused liquids.

- Flavor Infusion: N2O is highly soluble in fats and liquids, making it excellent for rapid infusion of flavors into oils, vinegars, and alcoholic beverages, significantly reducing traditional marinating times.

The operational advantages of utilizing large format cream chargers n2o like the 3.3L model are substantial. They drastically reduce the frequency of charger changes, leading to improved workflow efficiency in busy environments. Furthermore, the higher purity N2O contributes to better product consistency, extended shelf life of whipped products, and enhanced flavor profiles. This translates into tangible benefits, including reduced labor costs, less product waste, and an overall superior culinary output.

Manufacturer Comparison and Whipway's Competitive Edge

The market for N2O cream chargers features numerous manufacturers, each with varying levels of quality control, production capacity, and product offerings. When evaluating suppliers, key differentiators include gas purity, cylinder construction quality, safety certifications, and supply chain reliability. Many smaller producers may offer competitive pricing but compromise on crucial aspects like N2O purity (leading to off-flavors or inconsistent aeration) or cylinder integrity (posing safety risks).

Whipway stands apart by prioritizing uncompromised quality and safety. Our 3.3L Carbon Steel Cream Charger exemplifies this commitment, offering 99.9% food-grade N2O in a robust, meticulously manufactured carbon steel cylinder. We adhere to international quality standards, including ISO 9001, CE, TUV, and FDA compliance for our N2O gas, ensuring that our products meet the highest global benchmarks. Our extensive service years in the industry, coupled with rigorous testing protocols, have cemented our reputation as a trusted partner for B2B clients globally. We consistently invest in advanced manufacturing technologies and quality assurance programs, differentiating us through superior product performance, reliability, and unwavering customer trust.

Custom Solutions and OEM/ODM Capabilities

Recognizing the diverse needs of our B2B partners, Whipway offers comprehensive custom solutions and robust OEM/ODM (Original Equipment Manufacturer/Original Design Manufacturer) capabilities for n2 cream chargers. Whether you require specific branding on the cylinders, custom packaging designs, or unique N2O purity specifications for highly specialized applications, our team is equipped to meet your precise demands. We work closely with clients from conceptualization to final product delivery, ensuring that your specific market requirements are not only met but exceeded.

Our flexible manufacturing processes and dedicated design team allow for tailored solutions that reflect your brand identity and operational needs. This includes custom valve configurations, specialized coatings, and volume-specific solutions beyond our standard offerings. By partnering with Whipway for your N2O cream chargers, you gain access to a vertically integrated manufacturing process that ensures consistent quality control from raw material to finished product, coupled with the flexibility to adapt to evolving market demands.

Proven Application Cases and Customer Success Stories

Our n20 cream chargers have been instrumental in enhancing operational efficiency and product quality for a diverse range of B2B clients globally. For instance, a major chain of gourmet coffee shops integrated our 3.3L Carbon Steel Cream Chargers into their nitro cold brew and whipped cream stations. This transition led to a 40% reduction in labor time spent changing small cartridges and significantly improved the consistency of their beverage toppings, directly impacting customer satisfaction and increasing throughput during peak hours.

Similarly, a large-scale catering company adopted our larger capacity N2O cream chargers for their dessert preparation. They reported a substantial decrease in ingredient waste due to more precise aeration and an overall enhancement in the texture and presentation of their foams and mousses across thousands of servings. Our commitment to providing high-purity, reliable products translates into tangible operational and financial benefits for our partners, solidifying our position as a preferred supplier in the culinary gas industry. These real-world applications underscore the profound impact that high-quality, large-volume cream chargers N2O can have on commercial operations.

Trust and Support: FAQs, Delivery, Warranty & Customer Service

At Whipway, we understand that building trust with our B2B partners goes beyond just delivering a high-quality product. It involves providing comprehensive support, transparent processes, and reliable service.

Frequently Asked Questions (FAQs)

- Q: What is the purity level of your N2O cream chargers?

A: Our N2O cream chargers contain 99.9% pure food-grade Nitrous Oxide, meeting stringent international standards for culinary applications. - Q: Are your cylinders refillable?

A: Our current range of N2O cream chargers, including the 3.3L Carbon Steel model, are designed for single use to ensure safety and maintain purity standards. Proper disposal or recycling instructions are provided. - Q: What safety certifications do your products hold?

A: All our products, including 8g N20 cream chargers and larger units, comply with relevant international safety standards such as CE, TUV, ISO 9001, and our N2O gas is FDA compliant for food-grade use. - Q: How long is the shelf life of the N2O gas?

A: When stored correctly in a cool, dry place, the N2O gas in our chargers maintains its purity and effectiveness for 5+ years.

Delivery and Lead Times

Whipway operates a robust global logistics network to ensure timely and efficient delivery of our n2 cream chargers. Standard lead times vary based on order volume and destination but are communicated clearly at the time of order confirmation. For large bulk orders or custom solutions, a dedicated logistics coordinator works with clients to establish realistic schedules and ensure seamless delivery. We prioritize secure and compliant transportation of pressurized gas cylinders.

Quality Assurance and Warranty Commitment

Our commitment to quality is unwavering. Every N2O cream chargers unit undergoes rigorous multi-stage quality control checks throughout the manufacturing process, from raw material inspection to final product testing. We offer a comprehensive warranty against manufacturing defects, underscoring our confidence in the durability and performance of our products. Detailed warranty terms are provided with each purchase order.

Dedicated Customer Support

Whipway provides dedicated customer support to assist B2B clients with technical inquiries, order management, and post-sales support. Our experienced team is available to provide expert advice, troubleshoot issues, and ensure a smooth partnership experience. We believe proactive communication and responsive service are key to long-term client relationships.

Conclusion: The Future of Culinary Gas with High-Capacity N2O Chargers

The shift towards larger capacity, high-purity N2O cream chargers marks a significant advancement in the culinary and beverage industry. Products like the 3.3L Carbon Steel Cream Charger offer not just greater volume, but also unparalleled consistency, enhanced safety, and superior operational efficiency. For B2B decision-makers, investing in such advanced solutions translates into improved product quality, reduced operational overheads, and a competitive edge in a dynamic market. Whipway's commitment to precision manufacturing, stringent quality control, and comprehensive customer support ensures that our partners receive reliable, top-tier products that meet and exceed industry standards. Embrace the future of culinary innovation with confidence and the power of high-performance N2O solutions.

References

- Food and Drug Administration. (2023). Substances Generally Recognized as Safe.

- International Organization for Standardization. (2022). ISO 9001:2015 Quality management systems – Requirements.

- European Committee for Standardization. (2021). Pressure Equipment Directive (PED) 2014/68/EU.

- Gas World. (2023). N2O: The gas driving culinary innovation.

-

Whip It Like a Pro: Creative Uses for Whip Cream ChargersNewsAug.13,2025

-

Underwater Photography: Scuba Tank Stabilizer HacksNewsAug.13,2025

-

How Portable Scuba Tanks Are Revolutionizing Underwater ExplorationNewsAug.13,2025

-

Fun & Creative Uses for 8g Whipped Cream ChargersNewsAug.13,2025

-

Eco-Friendly Whipped Cream ChargersNewsAug.13,2025

-

Creative Uses for Cream Deluxe Chargers: Unlocking Culinary InnovationNewsAug.13,2025

-

From "Laughing Gas" to Lifesaver: A Deep Dive into the Critical Role of N2O in Modern MedicineNewsAug.08,2025

Related Products